Peeling

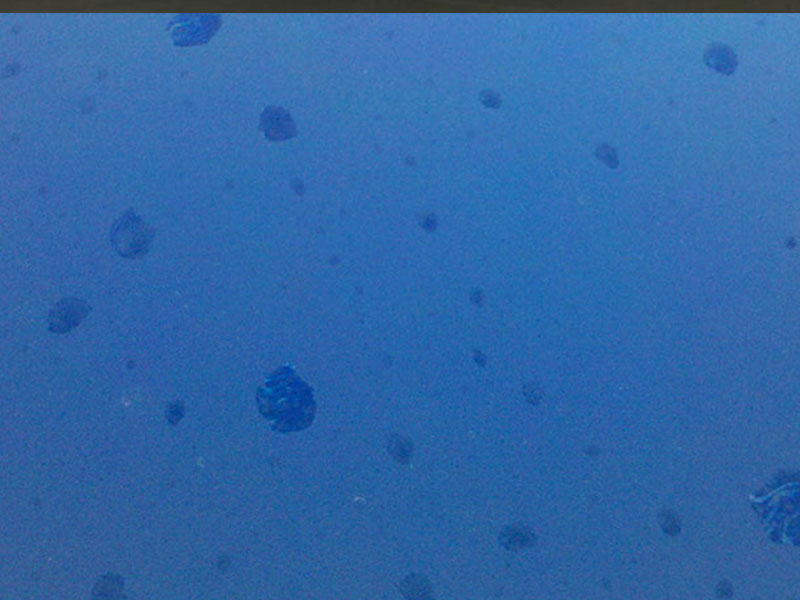

Phenomenon

A loss of adhesion or separation of the paint film from the substrate.

Cause

A. Improper preparation of the substrate. (Remaining moisture or oil)

B. Applying incompatible products together. (e.g. urethane and lacquer types)

C. Applying without sanding the previous paint film.

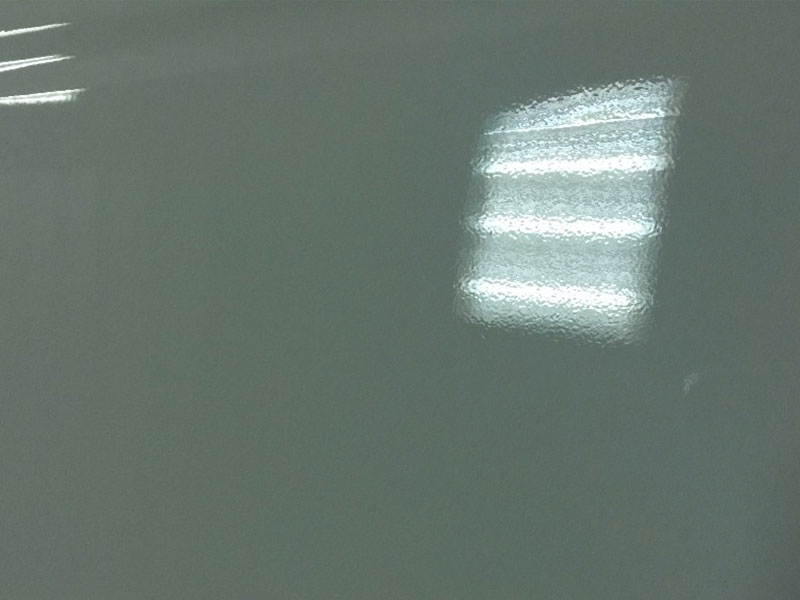

Repair

Remove the area wider than the damaged part and refinish.

Prevention

A. Clean and prepare the substrate thoroughly.

B. Use the recommended primer for the substrate.

C. Use compatible products by the system application.